How a Differential Works (and the Type of Gear Lube to Use)

Think of all the devices we take for granted that improve our lives. The refrigerator. The microprocessor. The air conditioner. The spork.

Add the automotive differential to that list.

Without that metal “pumpkin” beneath your vehicle filled with gears, clutches, bearings and gear lube, your wheels couldn’t rotate at different speeds and traverse different distances when taking a corner, meaning the outside wheel would skip and drag over the pavement. Not good for vehicle handling or tire maintenance.

So engineers developed the automotive differential, which we can organize into three general categories. Here, we present the basics of each and what you need to know to ensure your differential delivers years of solid performance.

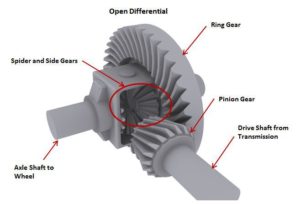

1) The open (or standard) differential

Likely what’s on your pickup truck, SUV or rear-wheel-drive car. A carrier holds a ring gear and spider and side gears. When you  take a corner, the spider and side gears allow the outside wheel to travel faster and farther than the inside wheel, resulting in a smooth, safe ride.

take a corner, the spider and side gears allow the outside wheel to travel faster and farther than the inside wheel, resulting in a smooth, safe ride.

- PROS: Cost-effective, excellent option for most stock vehicles. Provide predictable handling, reduced tire wear and little maintenance.

- CONS: An open differential directs power to the wheel with the least resistance. Anyone who’s driven on snow or ice quickly finds out what this means – one wheel can spin wildly while the opposite wheel receives insufficient power to move the vehicle, leaving you stuck.

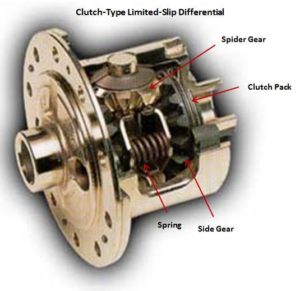

2) The clutch-type limited-slip differential

A clutch-type limited-slip differential attempts to solve the fatal flaw of the open differential, though it’s not a perfect solution.

When driving on a firm, dry surface, a limited-slip differential sends equal power to each wheel. But, when you hit the patch of ice or pit of mud that could leave a vehicle using an open differential spinning one wheel and going nowhere, a limited-slip differential supplies some torque to the wheel with grip, giving you a better chance of getting out of trouble. A limited-slip differential most commonly uses clutches to transmit torque between wheels. While a limited-slip differential doesn’t achieve 100-percent lockup, it is effective enough to get the job done most of the time.

Those clutches can slip, however

Clutch-based limited-slip differentials are ingenious devices, but they present a unique problem. When both wheels have ample traction, the clutch plates bind together tightly, sending consistent power to each wheel.

When one wheel slips, however, additional power is sent to the other wheel based on the frictional properties of the clutch packs. This is where the gear lubricant’s frictional properties play an important role in performance and wear.

However, differential manufacturers use different spring pressures and clutch disks made with different materials and surface areas. Additionally, spring tension and clutch friction properties change with age and wear. Consequently, frictional requirements of the fluid can vary. And if the frictional properties are not correct, abnormal clutch engagement and disengagement – called chatter – can occur.

However, differential manufacturers use different spring pressures and clutch disks made with different materials and surface areas. Additionally, spring tension and clutch friction properties change with age and wear. Consequently, frictional requirements of the fluid can vary. And if the frictional properties are not correct, abnormal clutch engagement and disengagement – called chatter – can occur.

Quit your chattering

Chatter is when the clutches repeatedly alternate between slipping and sticking instead of smoothly slipping. Chatter not only generates annoying noise and vibration, it also causes premature wear.

Instead of formulating multiple gear oils of the same viscosity, but different frictional properties to address occasional chatter in limited-slip differentials, you can use an additive in your gear lube that alters the fluid’s original frictional properties and eliminates chatter. AMSOIL synthetic gear lubes are already additized to account for the vast majority of applications. For unique cases where extra additive is recommended, we offer AMSOIL Slip Lock.

- PROS: Automatically distributes a percentage of the power to the wheel with better traction, helping eliminate getting stuck on low-traction surfaces.

- CONS: More expensive and can “chatter” if the fluid doesn’t provide the correct frictional properties.

3) The locking differential (or “locker”)

A locking differential uses mechanical devices to literally lock the two axles together. The wheels turn at the same speed and receive an equal distribution of torque. Lock up can occur manually or automatically depending on the unit. With the axles locked together, both wheels turn at the same time with the same amount of torque. That means one of them can still gain traction and move the vehicle if the other is suspended off the ground, for example in an off-road situation.

While lockers offer tremendous traction, particularly when driving off-road, vehicle handling suffers. Automatic lockers can send power to individual wheels in stages, resulting in a “ratcheting” effect that’s noticeable to the driver. They can also disengage suddenly, affecting handling. Lockers are usually reserved for off-road applications and used when moving slowly.

- PROS: Provides maximum traction in the toughest conditions for off-road vehicles.

- CONS: Can be noisy; reduced handling when the differential is locked.

What gear lube should I use?

Regardless which type of differential you have of those listed here, use a high-quality synthetic gear lube. Many manufacturers now install synthetic gear lube at the factory and recommend it as the service fill.

Modern differentials direct increased power and torque to the wheels compared to their predecessors, yet the differential gears and bearings remain largely unchanged. Plus, many differentials today use less gear lube and lower viscosities than before in an effort to reduce drag and increase fuel economy. In essence, less gear lube is responsible for providing more protection.

In this environment, inferior lubricants can shear and permanently lose viscosity. Once sheared, the fluid film weakens, ruptures and allows metal-to-metal contact, eventually causing gear and bearing failure.

AMSOIL Severe Gear® Synthetic Gear Lube is specifically designed for severe service. Its high viscosity index helps it lubricate better in cold conditions and maintain adequate viscosity to protect gears and bearings under high heat. It also costs less than most OEM-branded gear lubes.

It’s maybe not as cool as the spork, but it’s still a good product nonetheless.