Service Marine Lower Units to Prevent Water Damage

Preventing rust and other water-related problems in marine lower units.

Most other Marine Gear Oils fail to make the grade. We learn more on that from our own customers when they make the switch.

_by David Hilgendorf|April 24, 2023

_by David Hilgendorf|April 24, 2023

Water contamination

Water contamination is bad for several reasons:

Viscosity loss – Viscosity measures a liquid’s resistance to flow or thickness. Your marine motor’s lower unit is designed to use a gear lube of a specific viscosity for optimal wear protection. Water can reduce the gear lube’s viscosity below what the manufacturer recommends, reducing wear protection.

Foam – A film of gear lube forms on the gear teeth it protects. This fluid film absorbs pressure and prevents metal-to-metal contact. Water contamination, however, invites the formation of foam. As the foam bubbles travel between gear teeth, they rupture under the intense pressure leaving nothing behind to prevent metal-to-metal contact, which leads to premature wear and potential gear damage.

Sludge – Water produces sludge, inhibiting heat transfer and increasing the lubricant temperature, which speeds chemical breakdown. The faster the lubricant breaks down, the sooner it fails to provide adequate protection, and the sooner it must be changed.

Rust formation – Water contamination invites rust formation on metal surfaces. Rust can flake off and circulate throughout the gear lube, where it acts like sandpaper and scours bearing and gear surfaces.

The solution

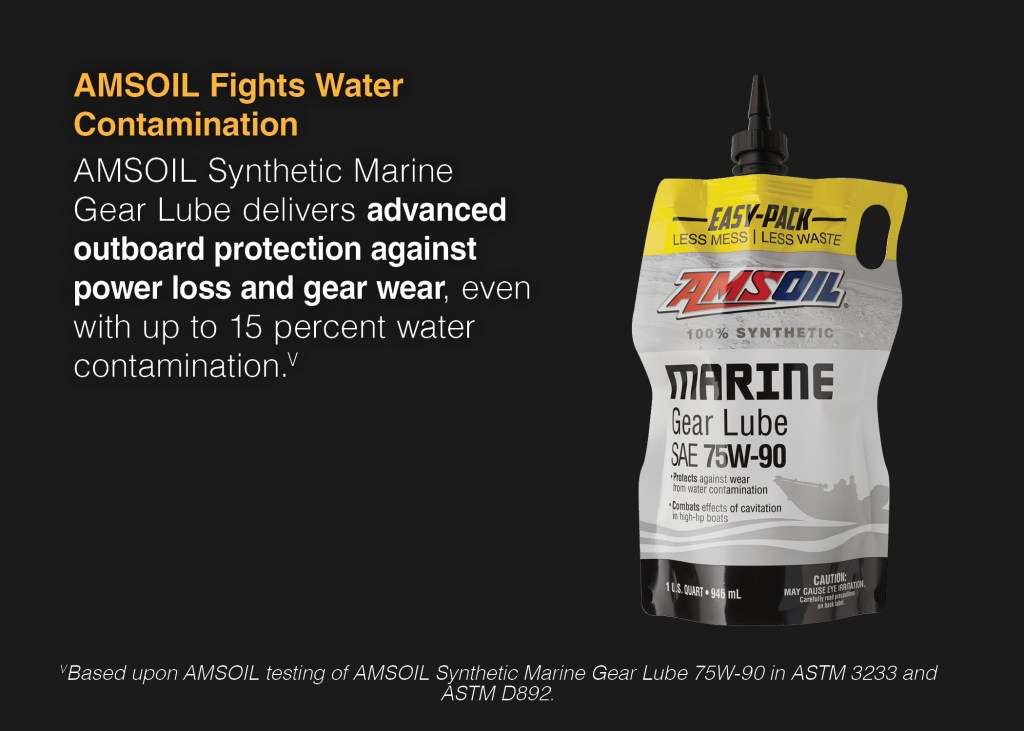

Avoiding contact with water is impossible when boating, so we’ve engineered AMSOIL Synthetic Marine Gear Lube to deliver advanced protection against power loss and gear wear, even with up to 15% water contamination.

WOW!!!

So next time you are about to place your expensive outdoor boat guy sunglasses up on the bill of your ball cap ask yourself if you checked and replaced you lower gear unit’s oil this year!!

Good Day