5 Expert Chainsaw Maintenance Tips

Chainsaws are great tools – when they’re working properly. Here are five chainsaw-maintenance tips to keep your chainsaw cutting strong.

Keep the chain sharp

Anyone who has tried forcing a dull chain through wood knows the importance of a sharp chain.

Properly sharpening a chain is an art form, so if you don’t want a collection of useless chains hanging on your garage wall, visit a professional.

It’ll likely cost you less than $10 and save you a ton of grief.

Oh, and the AMSOIL Bar & Chain oil keeps the chain cooler thus sharper longer. (We keep both gallons and quarts in Omaha)

However, if you’re like me and enjoy the challenge of learning a new craft, be sure to…

- Use the proper file size. The box the chain came in or your owner’s manual are two places to find that information.

- File at the correct angle. You can purchase a file gauge at most home centers that ensures you hold the file correctly.

- File each tooth the same number of file strokes (typically 3-6).

- Be careful with the depth gauges (the protrusions directly in front of each tooth). If you file them too much, the saw can bite too deeply into the wood and stall or, worse, pull you off balance. Again, use a gauge to ensure you sharpen the depth gauges correctly.

Properly tension the chain

A chain that’s too tight can bind and stall the saw. On a non-roller-tip bar, an over-tightened chain can overheat.

When adjusting the chain, hold the tip of the bar up as far as it goes and tighten the tensioning screw until you’ve taken the slack out of the underside of the bar.

Break in a new chain

When it’s time to replace the chain, break it in first by soaking it in bar and chain oil for a couple hours. This ensures all the pivot points are well lubricated.

Then, hang the chain from a nail and let the excess oil drip back into the pan.

Install and tension the chain and run until warm.

The chain will loosen as it heats, so shut the saw down and tension the chain again.

Then, perform light-duty work, like cutting limbs and small branches for 30 minutes or so. Tension the chain again, and you’re ready to dive into the heavy-duty work.

Find out why Soderlund’s Wood Mill using only AMSOIL.

Clean the air filter

Keeping the air filter clean is one of the most important parts of chainsaw maintenance to extend saw life and increase performance.

It’s the only line of defense against the engine ingesting sawdust and dirt, which can plug the carburetor and cause the saw to start hard and run poorly. Contaminants can also wreck the piston rings, causing the engine to lose compression, reducing power.

Many saws have a screen as opposed to a foam or paper filter. In these cases, use an air compressor to direct air through the filter backward to prevent lodging debris deeper into the media.

If you don’t have an air compressor, tap the filter on the edge of a workbench. If you have a foam or paper filter, replace it often – it’s far less expensive than replacing the entire saw.

Find out why different chainsaws have different oil mix ratios.

Use fresh gasoline for best chainsaw maintenance

Most homeowners’ chainsaws spend far more time sitting in the garage than cutting in the woods.

As gas/oil ages, gasoline can breakdown in as few as 30 days, creating gums and varnish that plug the carburetor and lead to hard starts and rough running.

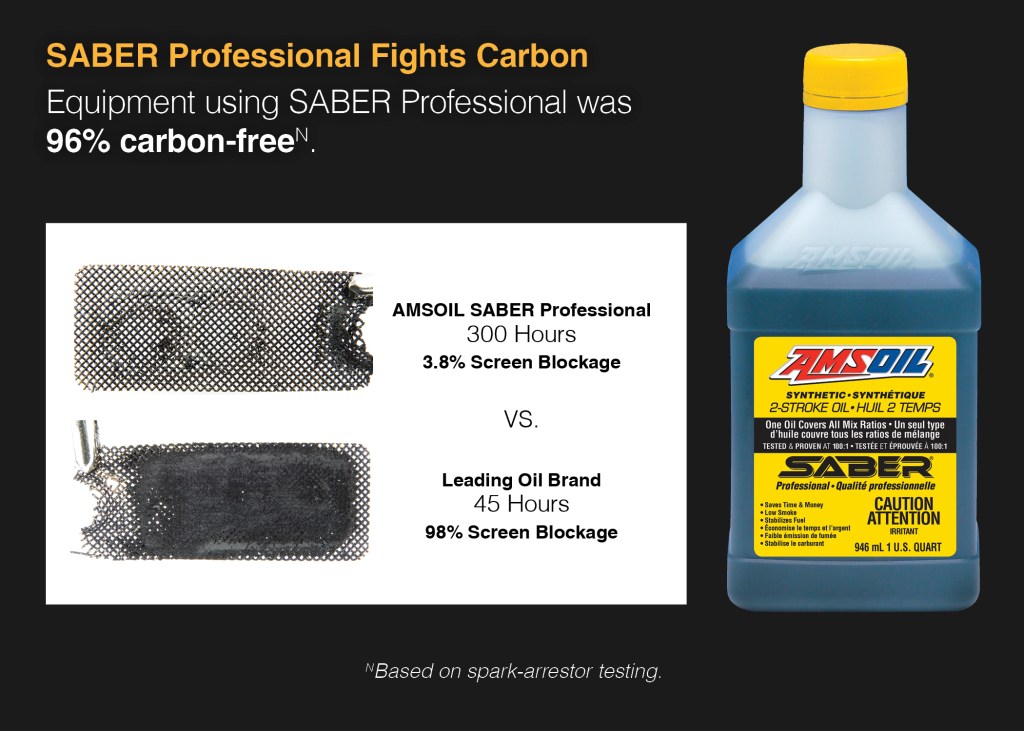

Mix only enough fuel to last 30 days. Better still, use a two-stoke oil formulated with a gasoline stabilizer, such as AMSOIL SABER® Professional Synthetic 2-Stroke Oil.

Not only is SABER Professional formulated with stabilizer, it also fights carbon to keep the exhaust port and spark-arrestor screen (if equipped) clean for maximum engine operability and power. Using a premium two-stroke oil is an overlooked, but vital, part of chainsaw maintenance.

You can also treat fuel with an additive designed to stabilize fuel, like AMSOIL Quickshot®. Both products keep gas fresh up to six months.